About Us

Established in 2017, Hayagreevaya Enterprise is one of the fastest growing companies in precision engineering domain. Though a young company, we compensate for our age with workforce that is highly experienced, infrastructure facilities that are top notch.

magic of Manfacturing

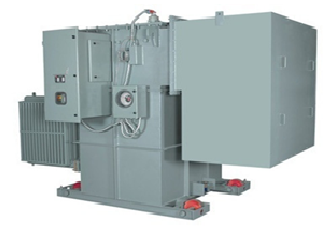

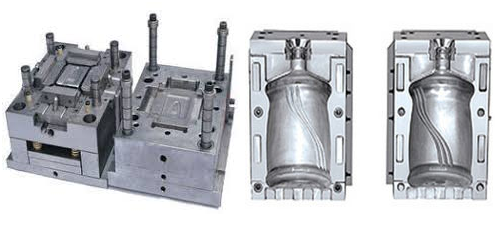

We are among the leading suppliers of precision engineering component products and heavy structural fabrication works. We also manufacture servo voltage stabilizers, rectifiers, transformers,Deep Hole Drill machine, Medical Equipment and various other industrial products. Our services also include cathode bar machining and copper plate inserts. We offer a broad product range for our valued patrons. Due to their easy operation, high performance and low maintenance the range of products presented by us is well appreciated across the market. We are able to leverage our highly experienced team and top notch facilities to create products that meet the industry norms every time, all the while being friendly to the client budget.

Our Infrastructure

Our state of the art facilities in Autonagar, Vishakhapatnam, an industrial zone promoted by APIIC (Andhra Pradesh Industrial Infrastructure Corporation) enables us to design and manufacture precision engineering components and products for our clients. Our infrastructure can be segmented into 3 operational units; General Fabrication, Precision Machining and Specialty Welding. This division helps us have dedicated team to focus on every job and ensure high quality on time delivery to our clients.

Integrity

We take pride in our team of well qualified and talented professionals. Each professional is chosen through a rigorous process involving screening tests based on the skills required and the past industry experience. To stay competitive in today's market we ensure constant value addition through well through our trainings that are scheduled and conducted throughout the year for different employee group. Job enlargement and job enrichment are both considered when planning employee growth.

LeaderShip

Operating our business under the leadership of our mentors, Mr. Anurag Paul and Smt. Radhika Paul, we have gained a distinct and repudiated position in the industry. Their successful and unique business strategies have made us able to cater a large number of client lists.

Why Us

With focus on the quality of manufactured products, we believe in building a long-term relationship with our patrons. The quality assured material are procured from trusted and authentic vendors and the entire products collection is strictly inspected to ensure only the range of best quality products is delivered to our customers. To achieve the optimum level of patron satisfaction, we also follow a customer’s detailed demands and are appraised for the same.

Success Factors:

High Quality Equipment

Techno-friendly infrastructure

Processes & procedures

High quality standards

Prompt delivery

Experienced competent workforce

Training & Development